CONSISTENT & AUTOMATED

OPTICAL SORTING

The Visar Sortop optical sorting machine is the latest, fully automatic electronic vegetable sorter ideal for high-quality optical sizing and sorting of carrots and potatoes. The Visar optical grader can sort any batch of carrots or potatoes consistently and efficiently, completely removing the need for manual sorting.

Tong is proud to be the UK’s sole distributor of the Swiss Visar Sortop carrot and potato sorters. Due to the success of its original carrot sorter, Visar now offers its advanced optical sorting technology in two models. A highly accurate optical carrot sorter, and an intelligent optical potato sorter.

consistently accurate

100% automatic

Visar optical sorting offers fully automatic optical sorting with the ability to size any batch of carrots or potatoes consistently and efficiently. Completely removing the need for manual sorting.

infrared vision

grade & weigh

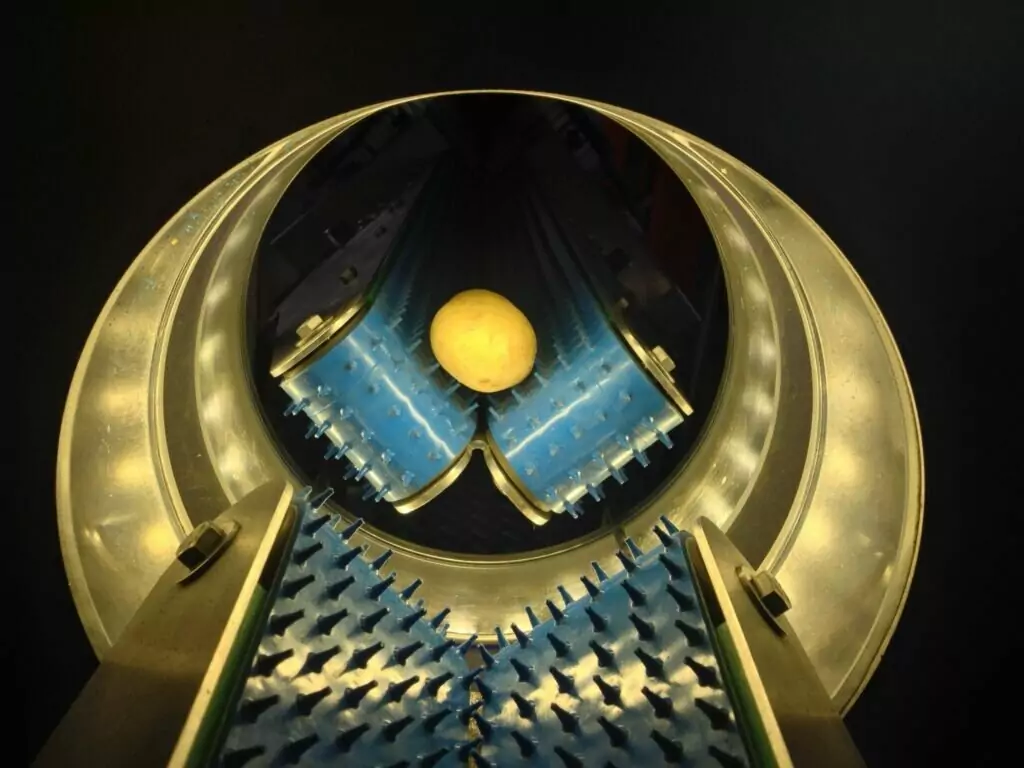

With 360 degree infrared vision, the Sortop offers the unique ability to detect any defect, as well as grading and weighing crop with great precision.

high throughput

12 to 15 per second

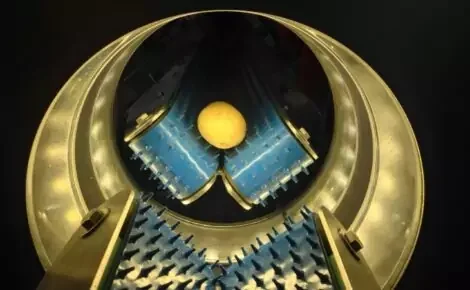

With each and every carrot and potato entirely analysed by the Sortop’s 360 degree mirror system, the Visar’s optical sorter offers exceptional accuracy at high throughputs.

features

MORE SALEABLE CROP

As well as removing the need for manual sorting, the Visar Sortop can also increase the percentage of crop that can be sold by up to 5%. The Sortop increases accuracy and consistency whilst identifying more saleable crop.

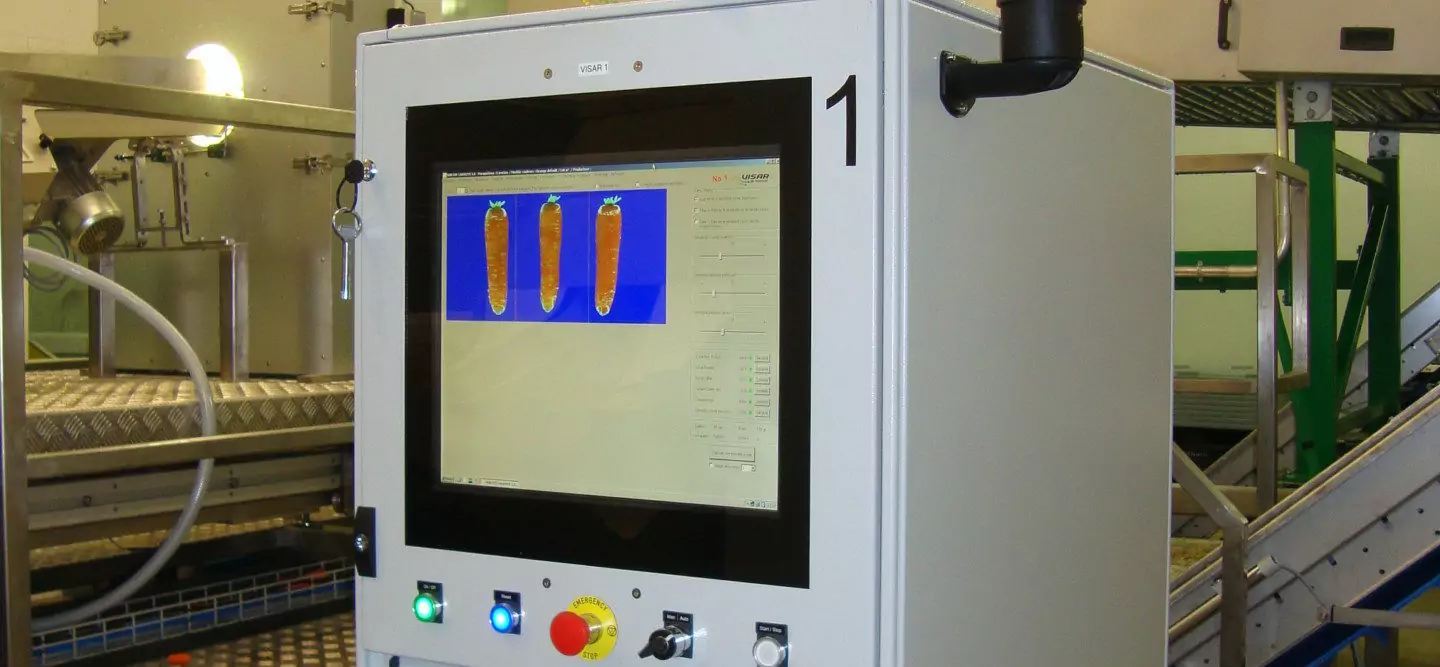

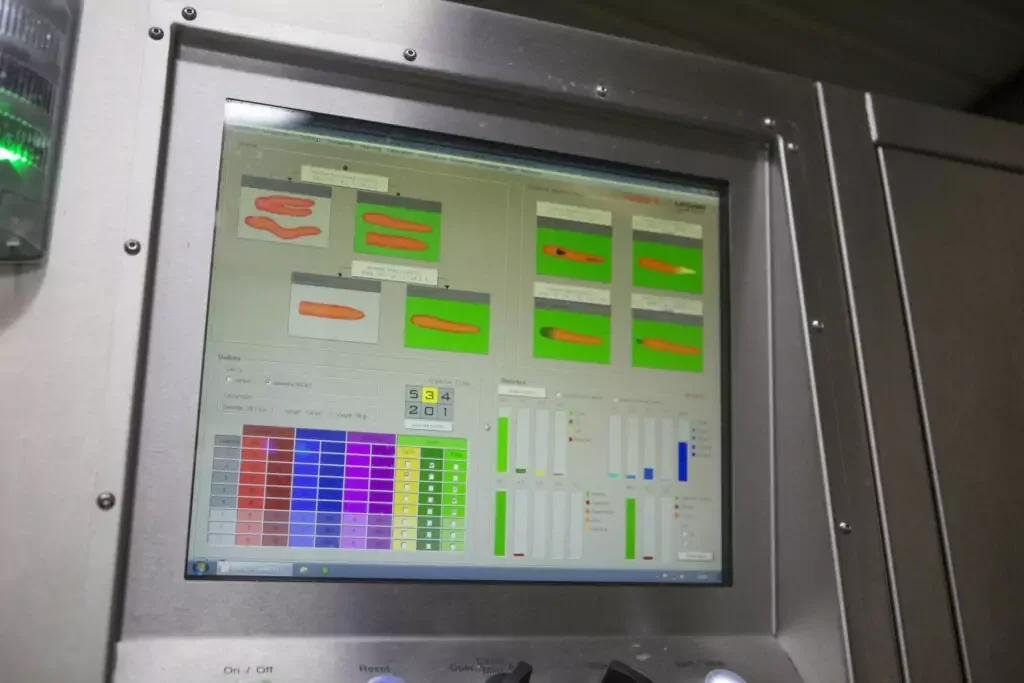

ACCURATE DETECTION

The high definition camera used within the Visar Sortop means that all defects are detected. Plus, the machine can even differentiate between a water stain and the tiniest black spot.

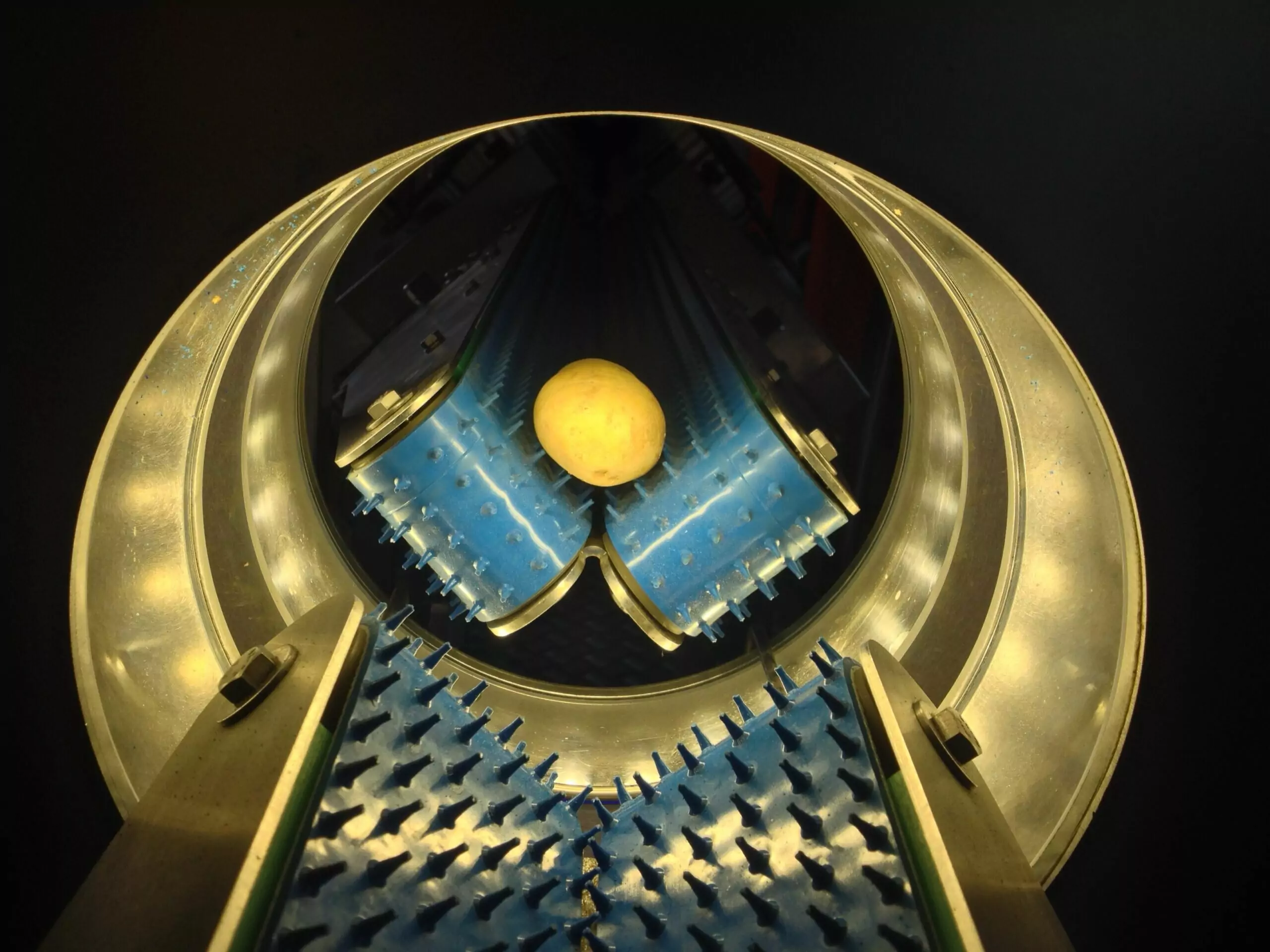

360 DEGREE VISION

The 360 degree mirror system means that every carrot and potato is entirely analysed, at an impressive rate of 12 to 15 carrots per second. This is the only reliable means of detecting any defects, whilst grading and weighing the carrots with exceptional accuracy to the nearest millimetre and gram.

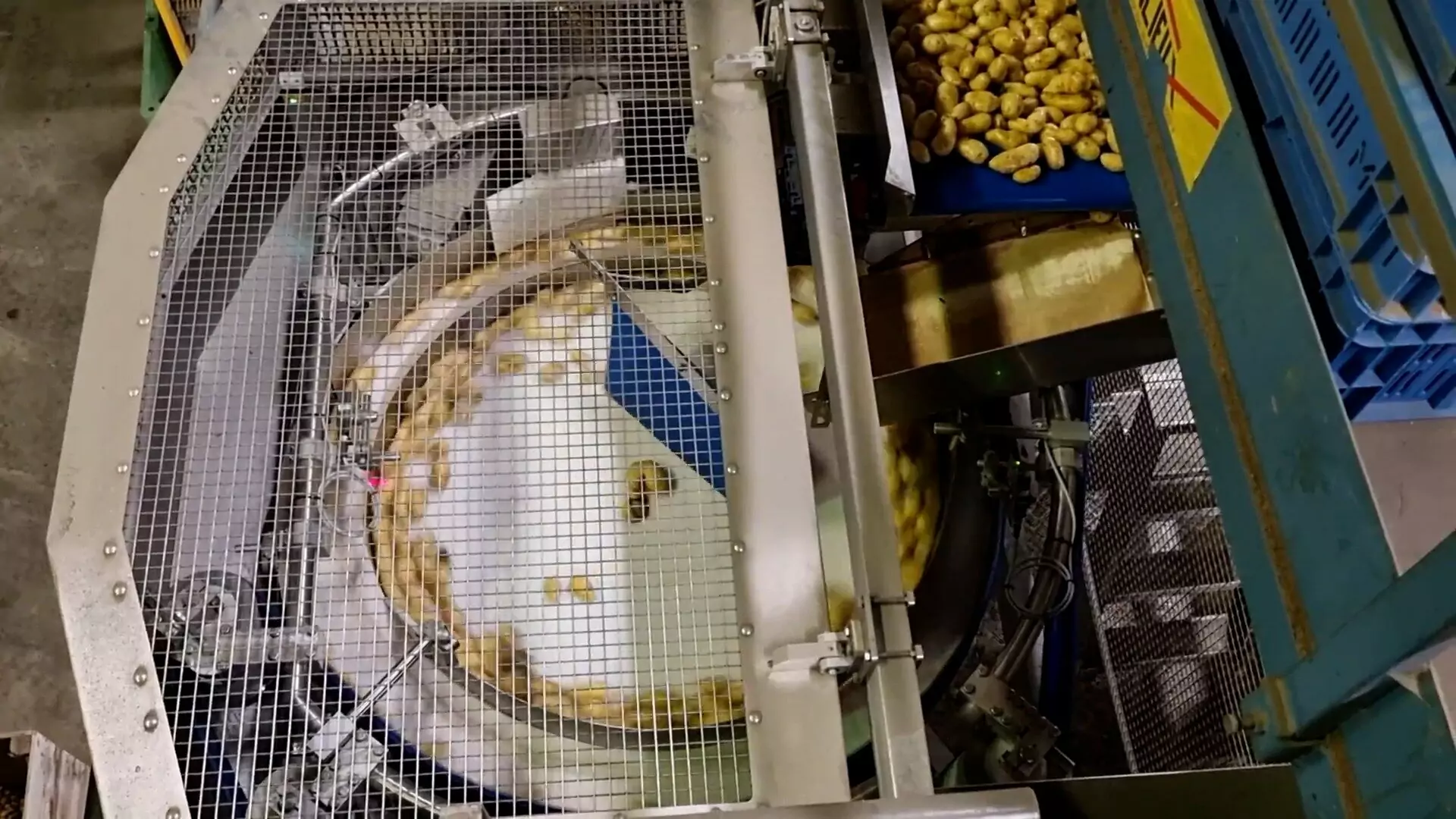

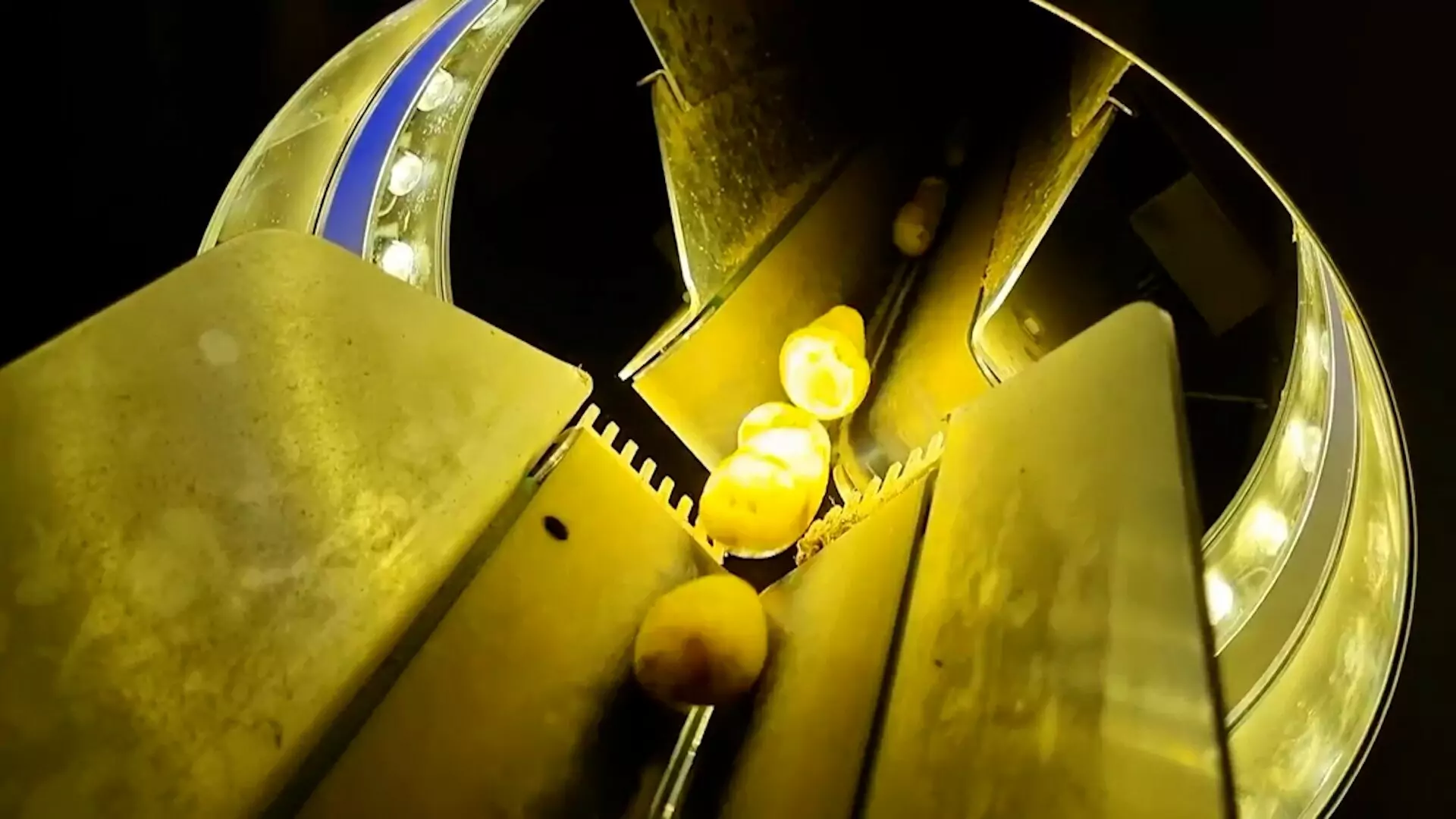

CAREFUL AIR EJECTION

A highly accurate nozzle system blows compressed air following a calculated trajectory, based on each carrot or potato’s dimension and weight.

GENTLE HANDLING

Crop is handled exceptionally gently with no drops. Soft-lined output areas ensure the highest quality crop with no damage or breakages.

NO MANUAL SORTING

The Visar Sortop is different from any other optical sorter on the market. It can sort your whole crop efficiently, automatically and without manual labour. Other sorters often require an extra manual sort, some need crop to be re-graded, and others don’t have a grading and weighing function. The Visar offers a completely automatic optical sorting solution.

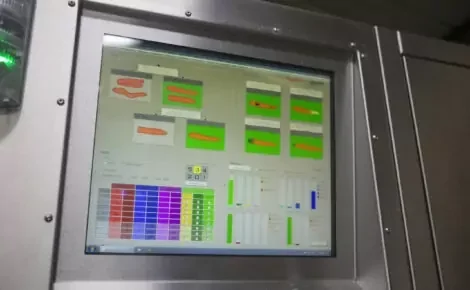

INTELLIGENT

AUTO-ADJUSTMENT

The unique software of the Sortop sorter really sets it apart from other optical sorting systems on the market. The exclusive design intelligent controls allow the system to work as if you were sorting manually, but with greater capacity and consistency.

The Visar-exclusive auto-learning software progressively and automatically learns what defects are acceptable and not, removing the removes the need for tedious adjusting and programming. This results in a very intelligent optical sorting solution which allows you to literally pass any batch of carrots or potatoes through the machine without adjustment.

UNIQUE CROP

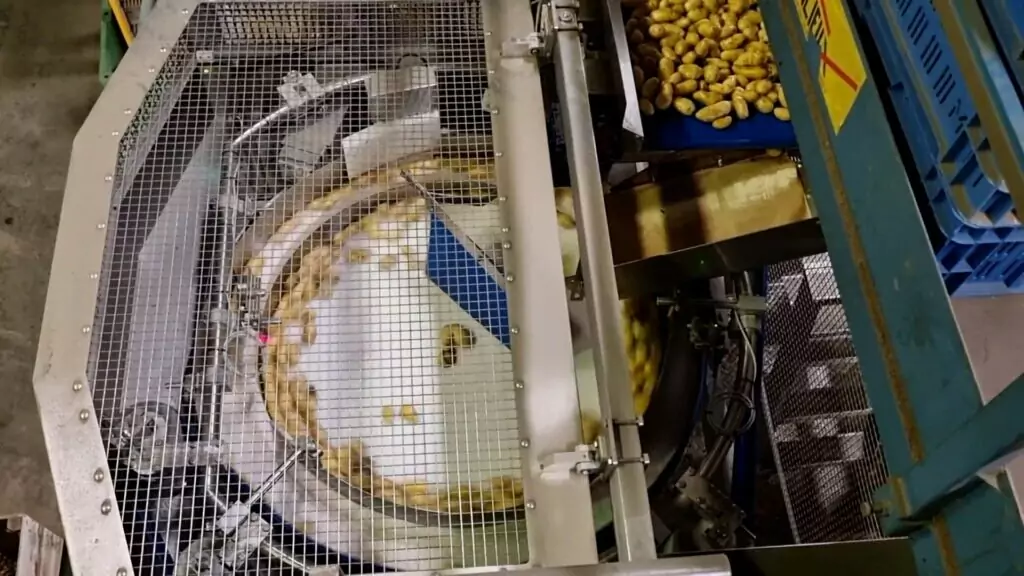

FEEDING SYSTEM

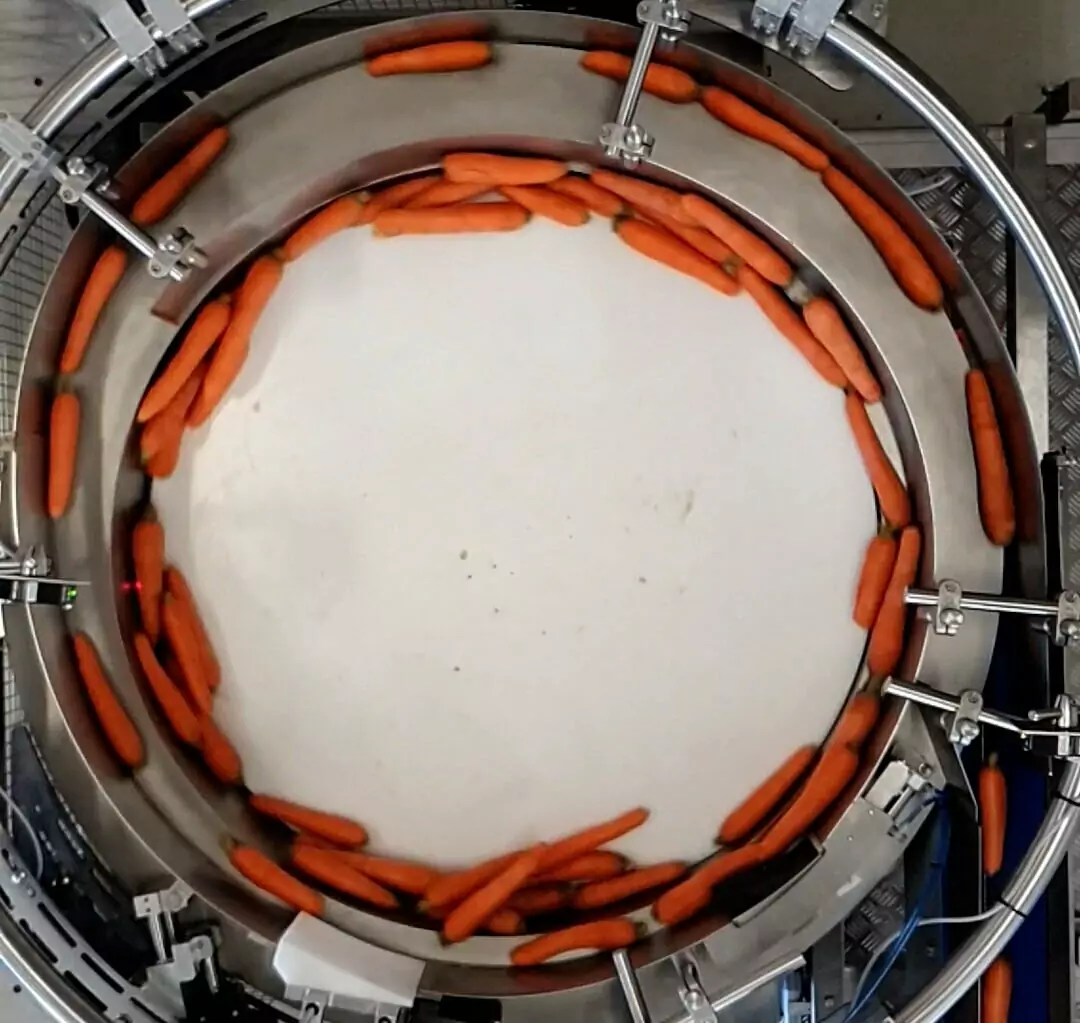

The simple and ingenious rotating system that feeds the Visar optical sorter aligns carrots or potatoes of all sizes, smoothly and without any duplicates, with an impressive sorting capacity of 1.8m of crop per second. This clever rotating infeed system ensure a continuous feed or carrots or potatoes to the sorter for maximum throughput and the very best optical sorting results.

SEE THE VISAR OPTICAL

SORTER IN ACTION

This video shows the latest carrot grading and sorting technology in action at one of the UK’s larger producers and processors of carrots, potatoes and combinable crops, M H Poskitt Ltd. Better known as Poskitts, the forward-thinking vegetable producer and processor has chosen leading handling equipment manufacturer Tong Engineering to design a new carrot handling facility in-line with their business objectives of long-term growth, whilst minimising crop wastage.