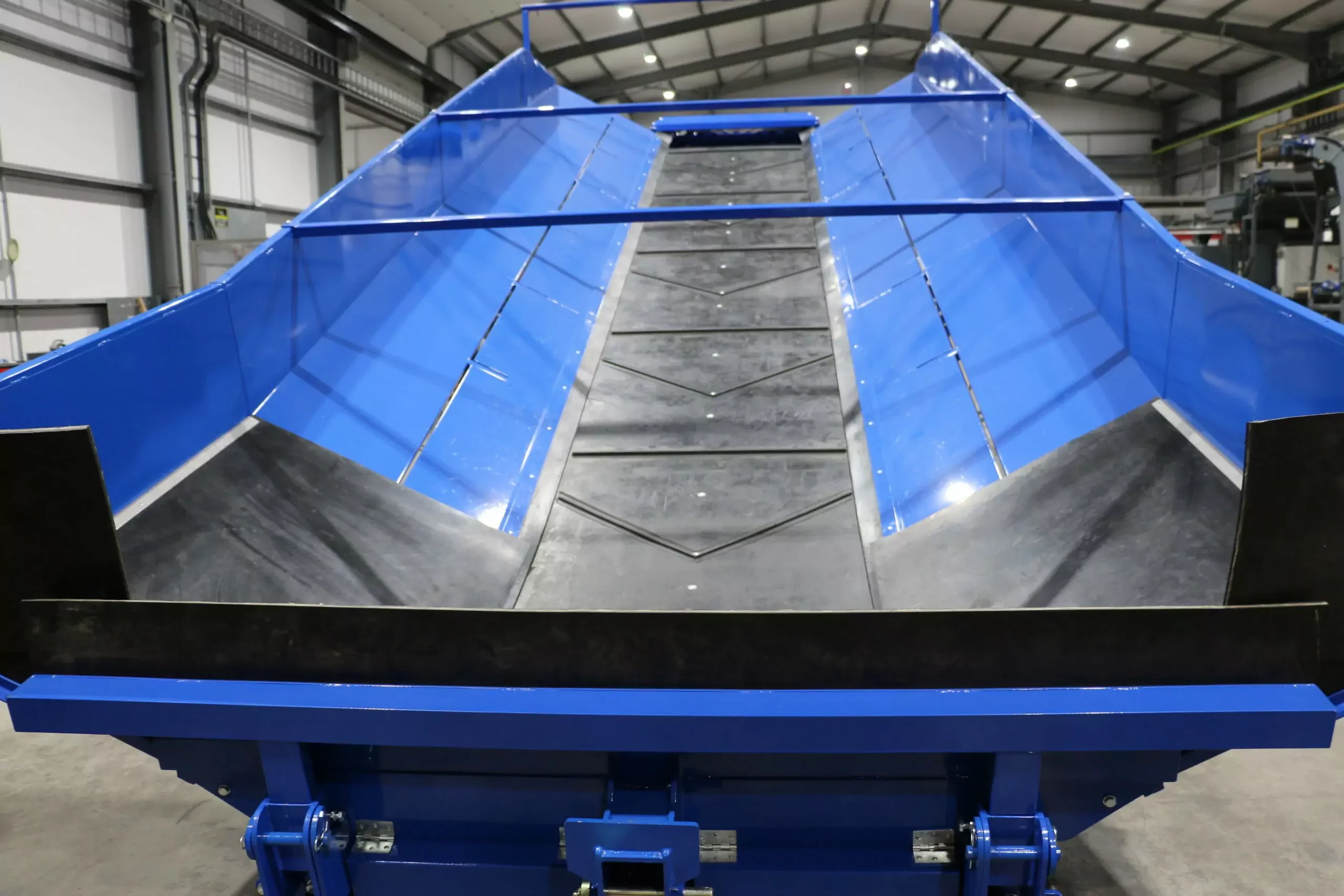

CUSTOM-BUILT INFEED UNLOADERS

With over 90 years of engineering experience, Tong offers unrivalled expertise in building the highest quality, robust and reliable infeed unloaders. Custom-built to perform in the most demanding environments, Tong vegetable unloader solutions are designed to offer ultimate longevity, featuring the heaviest duty drive systems and world-class components.

Manufactured to suit your exact product, capacity and throughput requirements, however large or small, when you choose a Tong unloader you can be sure of a dependable crop receiving and infeed system that can handle almost any material, in any situation.

GENTLE

EFFICIENT HANDLING

Tong infeed unloaders ensure exceptionally gentle handling of crop. With heavy duty construction yet carefully designed infeed and transfer points, Tong hoppers offer high throughputs yet minimal impact on crop.

CUSTOM BUILT

1.2M TO 2.4M WIDE

Manufactured in a wide range of widths as standard from 1.2 to 2.4m wide, Tong unloaders can be designed to suit your exact requirements, however large or small.

ALL ENVIRONMENTS

MILD OR STAINLESS

Suitable for outdoor dirty crop handling situations, or high-care crop packing environments, Tong unloaders can be built in mild or stainless steel construction to suit your application.

FEATURES

BLUE INVERTER TECHNOLOGY

All Tong unloaders feature Tong’s Blue Inverter Technology inverter direct drive motors which run on 87 Hz variable speed, offering over 50% less power consumption.

HEAVY DUTY CONSTRUCTION

Tong unloaders are built upon a heavy duty steel gauge design, consisting of chain and lathe construction. Featuring heavy duty 4” pitch chains as standard, with dual driven drive shaft, Tong infeed unloaders offer a total maximum strain of 64 ton. What’s more, unloaders wider than 1800mm are constructed with a central runner fitted to the unloader chassis, offering additional, robust support to the unloader lathes.

HEAVY DUTY BELTS

Tong unloader belts are built using heavy duty reinforced EP250 rubber chevron belting with vulcanised V cleats. They can also be specified with a heavy duty PVC pocket belt, depending on your requirements. The thick reinforced chevrons ensure effective emptying of the unloader as well as minimal rollback of product for the gentlest handling.

WORLD-CLASS COMPONENTS

Tong sources its equipment components from some of the world’s best renowned suppliers for quality, reliability and innovation. Including motors from SEW, Lenze and Motovario, rollers and drum motors from Interroll, bearings from RHP and SKF, and electrics from Eaton Moeller and Omron

RUBBER LINED INFEED

Tong infeed unloaders are lined with rubber ‘soft-landing’ at the infeed section for the gentlest receiving and handling of crop.

MOBILE HOPPER

All Tong infeed unloaders can be specified as a completely mobile unloader unit. Built upon a heavy duty chassis with robust 12.5 x 18 road wheels and removable heavy duty tow bar if required.

END TIPPING UNLOADERS

Tong’s rear infeed unlaoders offer the perfect unloader solution for intake of product from bulker lorries, trailers or similar. Fitted with flexible rubber seals, Tong’s end feeding unloaders create a seal between the unloader and the trailer during product transfer, to ensure no spillage. With a standard rear entry width of 3.1m, the Tong end tipping unloader can be manufactured with a choice of 1200mm, 1500mm, 1800mm, 2100mm and 2400mm wide belts, depending on your throughput requirements.

SIDE TIPPING UNLOADERS

Tong offers a range side tipping reception unloaders which are designed to receive product from bulker lorries, trailers and tipping buckets from the side, rather than the end. These side infeed unloaders are commonly specified where side tipping trailers are being used to feed crop. Or similarly, when a box or bag tipper is in place to feed crop into the unloader.

EVEN FLOW UNLOADERS

Also referred to as a ‘rise and fall’ unloaders, Tong manufactures a range of even flow unloaders. Designed to offer a controlled ‘buffer’ holding capacity at the infeed of the handling line, ensuring a continuous and steady flow of crop at all times. Ideal in situations where the vegetable handling line requires a constant feed of crop, the even flow unloader is often used when feeding specialist weighing and packing equipment. Offering maximum flexibility and throughput. The conveyor in the unloader starts in an ‘up’ position, and as it is fed, the conveyor lowers to create the holding capacity. Once the conveyor starts moving, the belt rises to feed crop onto the line. The even flow unloader is integrated with the vegetable handling line’s controls, and a sensor controls the infeed to the line as it is required. Maintaining a continuous feed of crop.

HIGH CAPACITY UNLOADERS

Tong offers a custom built unloader solution to suit all handling requirements, including high capacity infeed unloader to feed bulk materials safely and effectively. Whatever your handling need, Tong can design a unloader that will perform in the most demanding situations with high capacities and heavy duty operation.

WET UNLOADERS

Tong wet unloaders ensure an exceptionally gentle reception of crop at high throughputs. Suitable for the infeed of dirty or clean vegetables including potatoes, carrots, parsnips, swedes and more. Tong wet unloaders receive crop carefully and transfer it onto an outfeed web piler where crop is drained as it exits the unloader. Wet infeed unloaders are popularly specified in packhouse environments as the presence of water means that excess debris, soil and sand separates from the crop within the unloader. Giving the crop a light soaking action, which can be enhanced when crop is left to ‘soak’ in the tank for longer dwelling times. All debris from the crop is then easily removed from the tank via the wet unloader’s dump valves. With the option of an integrated tank auger for even more effective accumulation and removal of soil and debris.

FOLDABLE UNLOADER

For situations where the unloader needs to be transported, often in areas where space is tight or narrow. Tong’s foldable side unloader offers robust design, with optimum mobility.