Tong Engineering is set to showcase its latest vegetable barrel washer at this year’s Interpom potato, fruit and vegetable event in Belgium. Exhibiting at the event on stand 102 from 27th to 29th November, the UK’s leading vegetable grading and handling equipment manufacturer Tong Engineering, will be displaying a high capacity stainless steel barrel washer which has been sold to a leading potato producer in France.

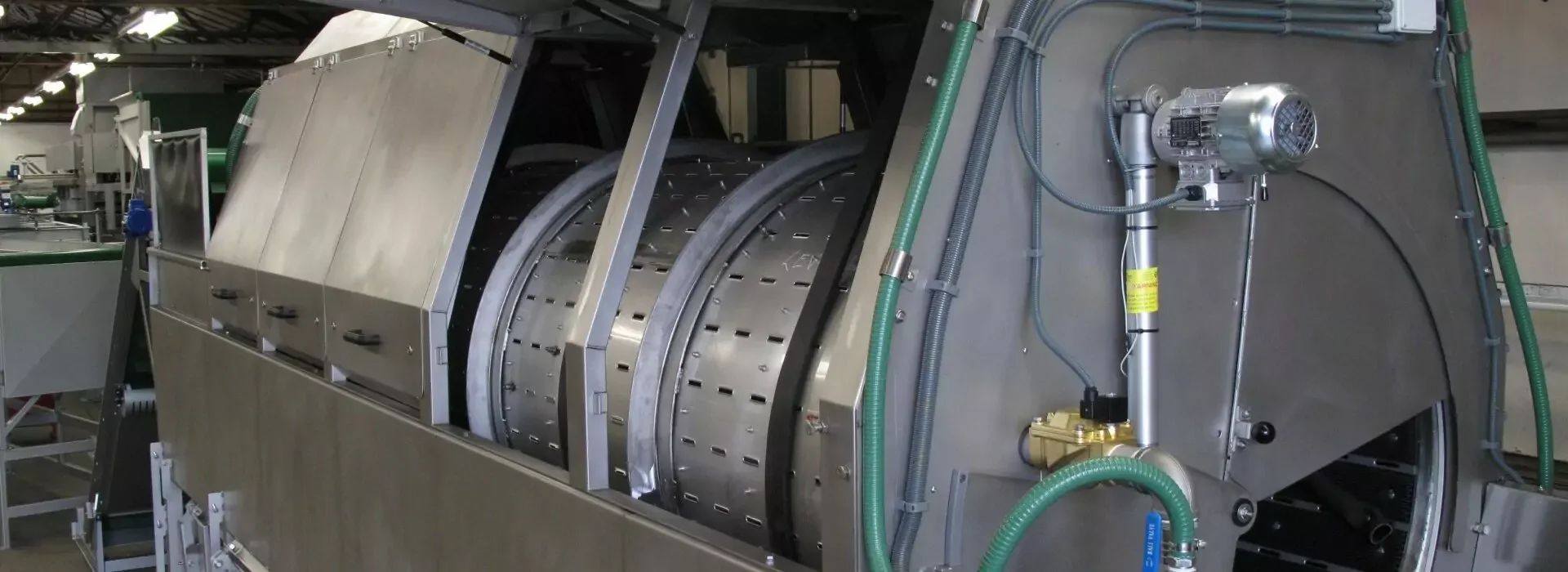

Featuring an integrated vegetable destoner, for the effective removal of stones and debris prior to washing, the latest model of Tong’s market leading barrel washer is designed to incorporate the most advanced technology, offering effective washing results in the most demanding vegetable washing situations, as well as ensuring the gentlest handling of crop.

Built with Tong’s Blue Inverter Technology direct driven motors, the barrel washer runs very efficiently and with minimal maintenance requirements. In addition, maintenance and cleaning can be performed with ease with heavy duty barrel side-guards that offer easy-access cleaning facilities for simple maintenance.

“The design of our barrel washers has developed over recent years to ensure the most reliable performance, and low maintenance requirements. This allows customers to run the washer continuously for maximum throughput and minimal downtime,” explains Charlie Rich, Export Sales Manager at Tong Engineering. “The latest models of our barrel washers really are world-class, with our most recent installations of high-capacity vegetable washlines now operating in Poland, France and Sweden, on a wide range of vegetables from potatoes and carrots to celeriac and parsley root” adds Charlie.

“With a rubber lined infeed chute, and heavy duty construction and guards, Tong barrel washers are very gentle on crop whilst being very robust, resulting in an efficient crop washing system that is reliable, energy efficient, requires minimal maintenance and offers consistent performance in all washing situations from 2 to 30 tonnes per hour,” says Charlie.

“The barrel washer that we will have on show at Interpom has been specified to suit our French customer’s requirements, and as well as an integrated destoner at the infeed which gently flumes crop into the barrel, the washer also incorporates high pressure booster spray bars within the barrel to add an additional washing action, for an enhanced washed finish. The presence of the high pressure spray bars means that the washer has a two level washing ability; submissive washing where crop is submersed within the barrel in the washer’s water tank, or as a spray washer, depending on the customer’s requirements. ”

One customer, Michał Gulczyński of Polish fruit and vegetable producer Polfarm said “Our new Tong carrot grading, washing and polishing line features two Tong barrel washers capable of processing up to 40 tonnes of carrots per hour. With the increased capacity that the new line offers, we are able to process more crop per hour, meaning running and labour costs are significantly reduced whilst output is increased. Not only that, the new washing lines are very easy to maintain which saves our operators a lot of time.”

“Exhibiting at Interpom is a great chance for us to meet with visitors from all over the world and showcase our latest machinery, and we are very excited to be displaying our latest vegetable barrel washer on our stand this year. With big developments in intelligent touch-screen technology and controls, as well as energy efficiency and advanced design, this year’s exhibit will give visitors a great opportunity to view our latest barrel washer and discuss their upcoming vegetable handling requirements,” added Charlie.