EFFICIENT, SAFE & GENTLE

BOX DUMPING

The Tong 150° Box Dumper is built to last with robust construction and gentle handling at the heart of its design.

Built to offer reliable performance alongside high throughput dumping of almost any product including potatoes and vegetables, the 150 degree box dumper is a popular choice for a continuous flow of crop onto any vegetable processing line. Its advanced design allows boxes to be emptied fully with hassle-free, automatic operation. Our most popular dumper for complete and efficient box dumping.

150° Box Dumper features

HYDRAULIC LID

Tong offers an automatic hydraulically operated clamp box lid as an option on all box dumpers. The hydraulic lid automatically lowers onto the top of the box once the box is placed in the dumping cradle. This ensures a secure hold of the box within the dumper, and completely removes the chance of any spillage of crop. When a full clamp lid is fitted, the 150° Box Dumper incorporates a hydraulically opening flow door which opens to release crop once the box is tipped. A half clamp lid can also be fitted meaning half of the lid is open, so as the dumper lifts in increments, controlled by crop sensors, the crop gently flows out of the box.

FORWARD CONVEYOR

The option of an in-line forward conveyor is a popular choice for a continuous and even feed of crop from the dumper, as well as offering holding capacity whilst the box or tote is changed. The forward conveyor is fitted at the outfeed of the dumper and is available in two standard options – 1.8m long x 2m wide or 3m long x 2.2m wide. The crop conveyors are powered by inverter direct drive variable speed motors, and a crop sensor fitted to the top of the conveyor controls the tipping mechanism and the even flow of crop from the tipper to the conveyor. Should there be no crop or a gap in the flow of crop on any part of the belt, the crop sensor automatically accelerates the belt until crop reaches the end of the belt, then the speed returns to normal.

CROSS CONVEYOR

Similar to the in-line forward conveyor, the option of a cross conveyor is offered at the outfeed of all Tong dumpers. The 150° Box Dumper helps to ensure a continuous flow of crop, and offers crop-holding capacity whilst the box is changed. It is particularly popular where crop is required to flow at a 90 degree angle from the orientation of the dumper, often where space is limited.

BUILT-IN POWER EFFICIENCY

All Tong box dumpers are built with an energy efficient power-saving mode which identifies and shuts-off the dumper when not in use.

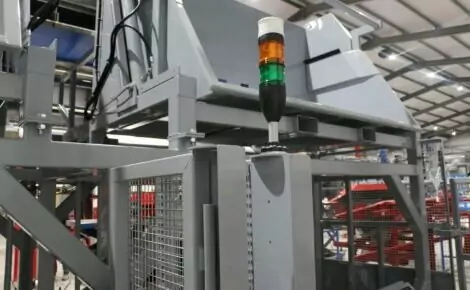

OPTIMUM SAFETY LIGHT GUARDS

The 150° Box Dumper is designed to meet stringent safety standards, featuring a box/bag movement siren and empty beacon, as well as light guards, which meet the full requirements of EC legislation. The light guards become active when the dumper cradle begins to lift and any breaking of the security beams will stop the machine.