NEXT-GENERATION VEGETABLE POLISHING

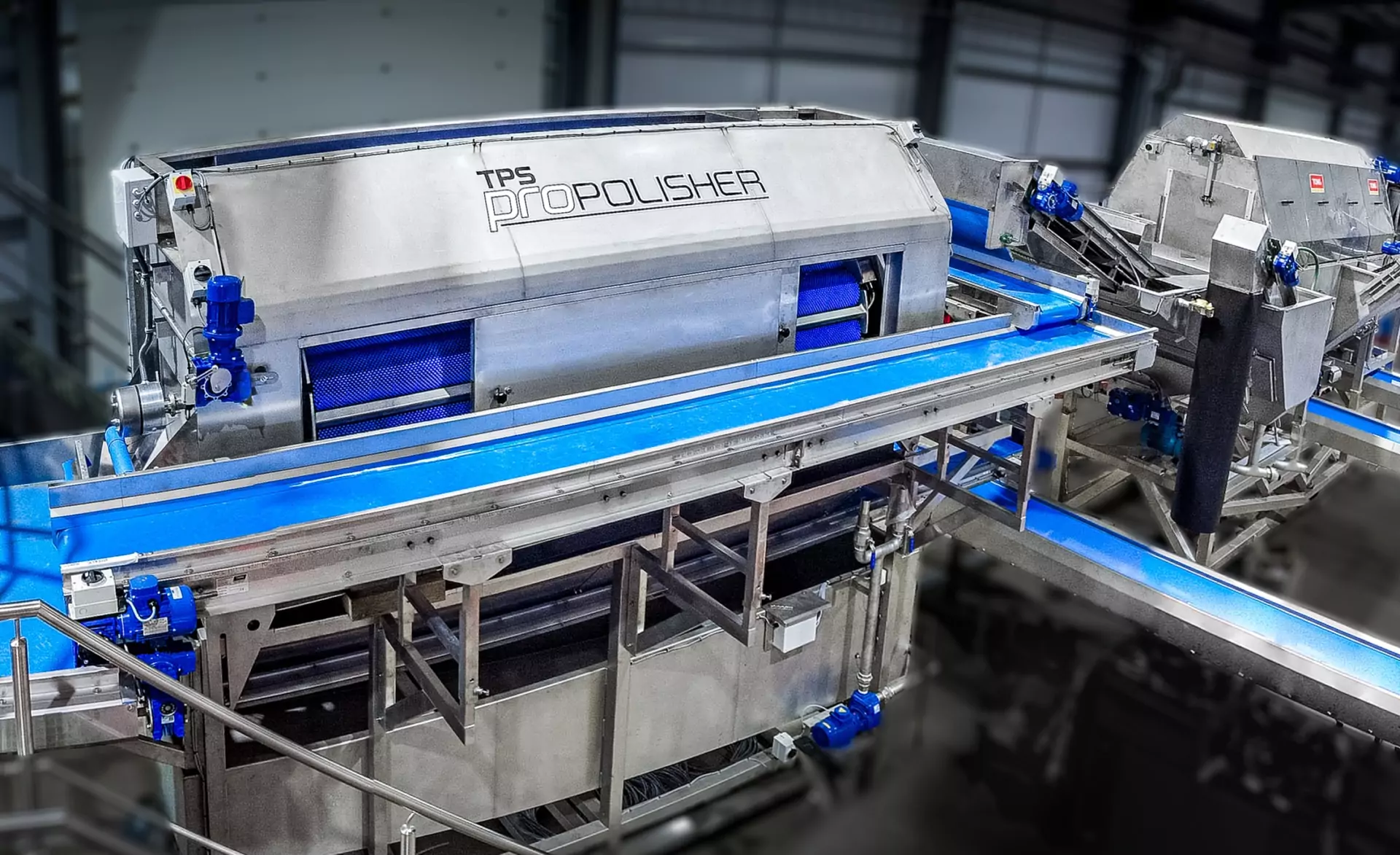

The TPS-PRO vegetable polisher is Tong’s next-generation vegetable polisher featuring electric direct drive on every shaft, offering virtually maintenance-free operation with high-quality crop polishing results.

Popular for effective vegetable polishing of a wide variety of root crop from potatoes and carrots to parsnips, beetroot, celeriac and more, the TPS-PRO vegetable polisher is most commonly used for high quality carrot and potato polishing and is suitable for throughputs between 15-30 tons per hour.

So, when you choose the TPS-Pro vegetable polisher you can be sure of a reliable solution to remove dirt, debris, and blemishes from the vegetable’s surface, giving it a cleaner, more attractive appearance prior to packing.

unique design

minimal maintenance

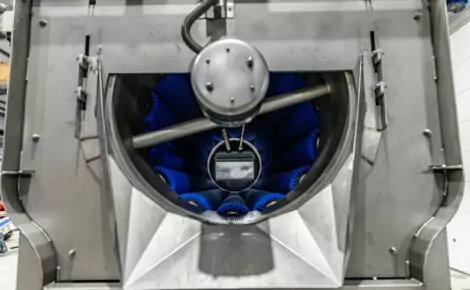

With self-contained, water-proof sealed inverter direct driven motors on every shaft, the TPS-PRO Polisher is virtually maintenance free.

two models

14 & 18 brushes

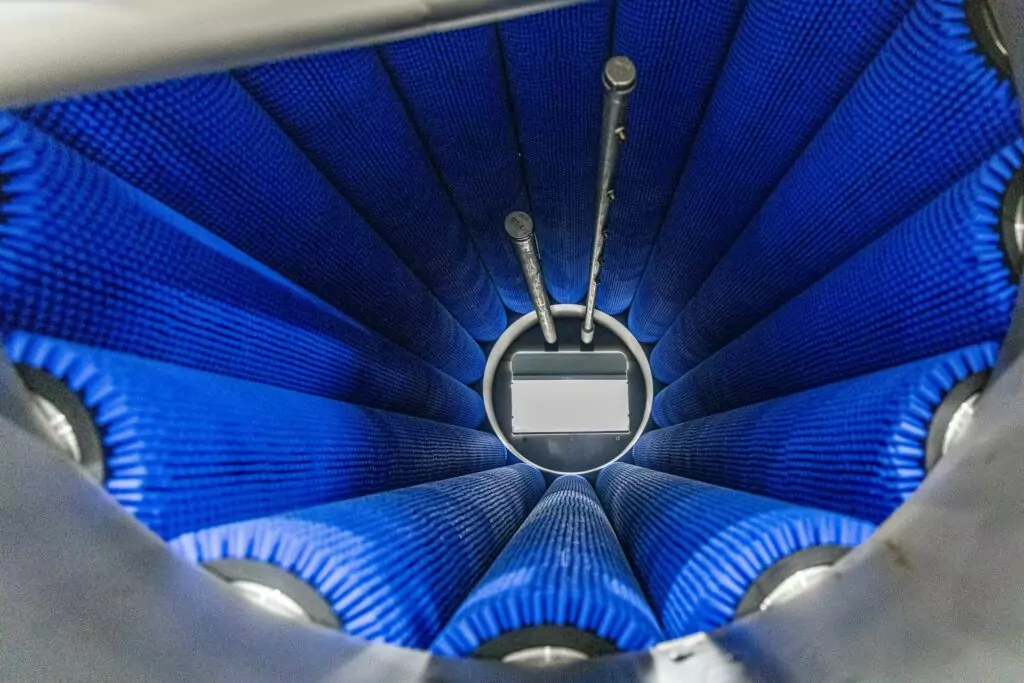

Manufactured in two standard models with 14 or 18 brushes and barrel lengths of 3m & 3.5m long, the TPS-PRO vegetable polisher is built to suit your specific requirements.

high throughput

POLISH FROM 10 to 30 tph

Built to perform under the most demanding vegetable polishing situations, the TPS-PRO Polisher is suitable for high throughput polishing up to 30 tons per hour.

EXPERTLY DESIGNED

FOR ALL

THROUGHPUTS

The TPS-PRO Polisher is uniquely designed to provide a reliable polishing machine for improving the appearance and marketability of potatoes, carrots and other root crops at high throughputs.

So, whether you’re looking for a potato polisher to be integrated into a new or existing vegetable washing and processing line, or a stand-alone carrot polisher, Tong offers an advanced polishing solution that will stand up to your crop polishing demands.

Features

HEAVY DUTY BUILD

Built to the highest standards with heavy duty stainless steel construction, the TPS-PRO Polisher is built to last.

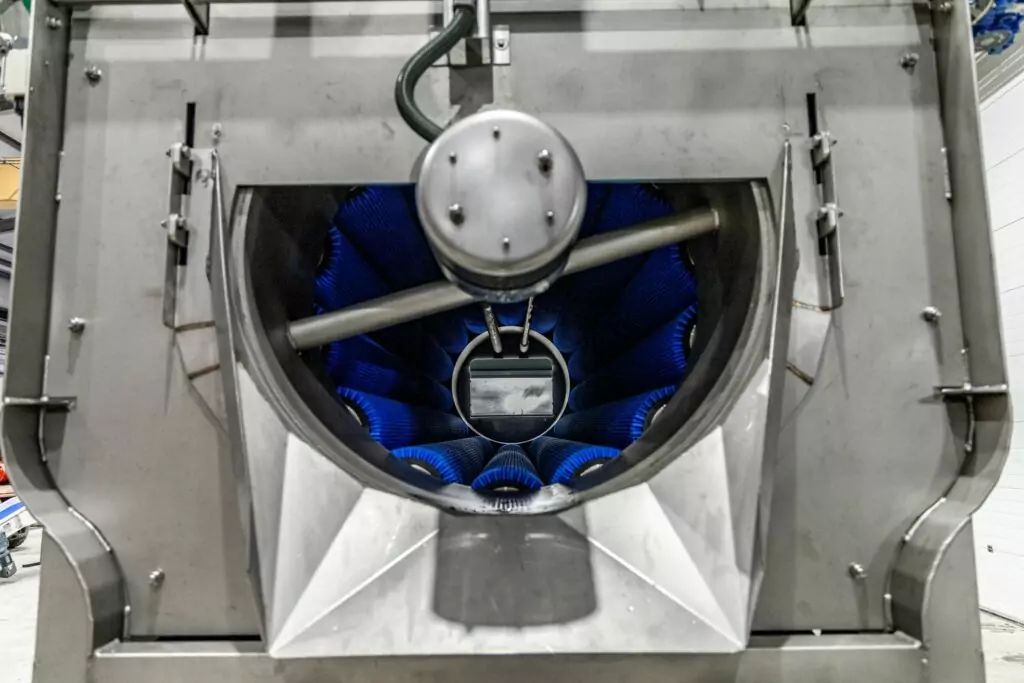

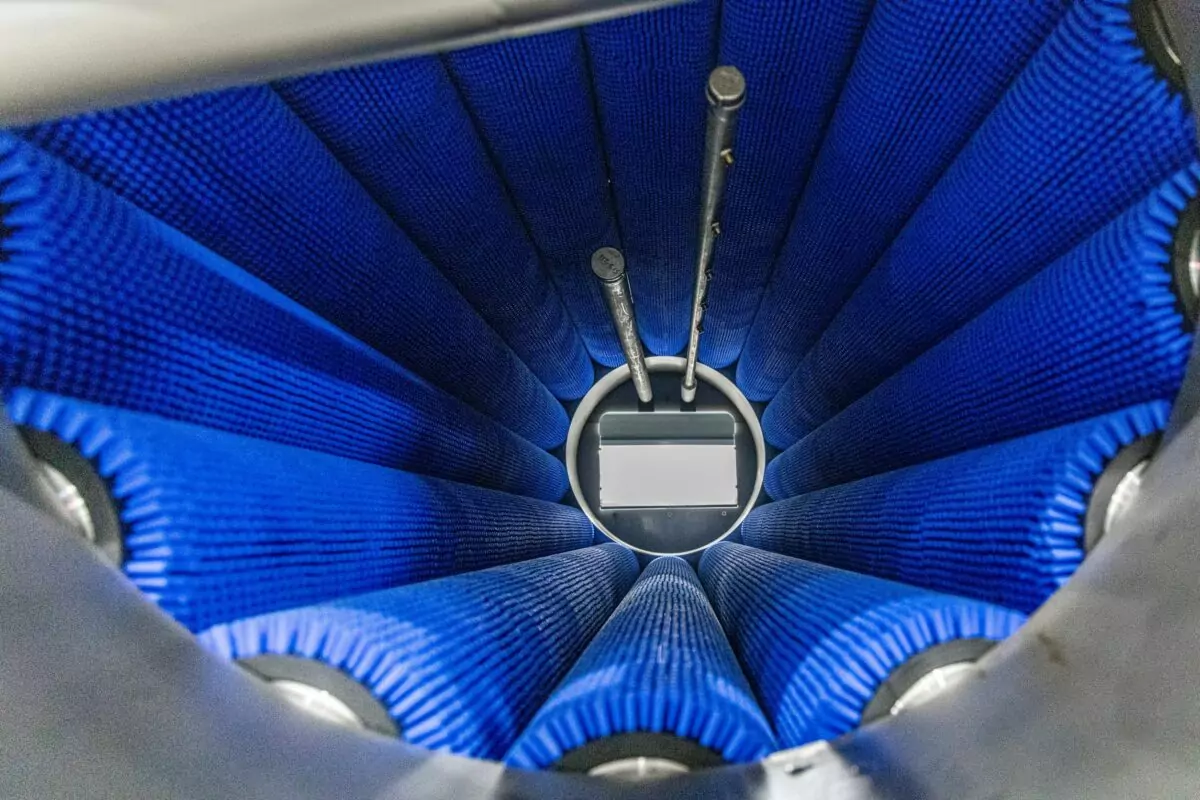

The root veg polisher barrel features a series of durable brush shafts that each rotate to gently brush crop, removing soil, debris and surface blemishes for a clean, polished finish. The carefully designed brush shafts allow crop to gently tumble through the barrel before exiting the polishing machine onto the next part of the handling process.

WATER SPRAY BAR

For enhanced crop finish the TPS-PRO Polisher is fitted with a high pressure water spray bar which ensures crop is rinsed as it passes through the polisher. Crop is also sprayed by a final rinse spray bar as it elevated out of the polisher for the perfectly polished root veg every time.

STAINLESS STEEL CONTACT POINTS

The TPS-PRO Polisher features stainless steel contact points for optimum longevity and efficiency.

RELIABLE POLISHING

With exceptional polishing results and minimal maintenance requirements, the TPS-PRO Polisher offers hassle-free polishing that keeps up with demands. This quality root veg polisher also features a unique air-bag system for angle positioning of the polisher tank, ensuring optimum crop movement and vegetable polishing results.

HIGH QUALITY FINISH

The TPS-PRO Polisher drive system is built upon state-of-the-art engineering design, featuring the highest quality components for continuous operation and a high value finish.

OPTIONAL EXTRAS

The TPS-PRO Polisher is built to suit your exact requirements. Choose from a selection of optional extras including a bespoke water recycling system, bypass system, filter elevator and re-circulation pump.

VIDEO: See the TPS-PRO VEGETABLE POLISHER in action

- Unique Design

- Direct Drive Motors on every shaft

- Virtually maintenance-free

- Ultimate performance, gentle handling

- Unrivalled vegetable polishing results