AUTOMATED PALLETISING SOLUTIONS

Tong Engineering is the official UK distributor of Dutch-manufactured Verbruggen, known across the world for their high quality palletising solutions.

Designed for quality and durability, Verbruggen palletisers deliver an incredibly stable stack and consistent performance.

Verbruggen’s palletising machines are manufactured to ensure quick, efficient and uniform stacking of bags, boxes and crates on pallets or sheets, Verbruggen palletisers offer precise product stacking capabilities at any speed, resulting in a palletiser for every throughput with various automatic and semi-automatic options.

SUPERIOR FUNCTIONALITY

Verbruggen palletising solutions can handle bags from 2.5 kg up to bags of 75 kilos, boxes in different size and bags in boxes. Over the years the design and construction of Verbruggen machines has improved constantly, resulting in a current superior functionality, reliable equipment and great product results by our world-famous palletising machines.

HIGH SPEED PACKING

Automated stacking of bags, crates or boxes from 10 to 40 bags per minute and up to 120 boxes per minute. Perfect for a wide range of crop.

ULTIMATE FLEXIBILITY

With up to 20 possible stacking patterns allowing customers to choose the best stacking patterns when palletising different sizes of bag as well as being able to combine bags, boxes and stack bags in boxes.

CUSTOMISED PALLETISING SOLUTIONS

Verbruggen palletising solutions not only bring a significant reduction in labour costs and downtime, but also utilise loading space in the most efficient way. In addition to its comprehensive palletiser range, Verbruggen solutions also include wrapping machines, strapping machines and check weighers.

SEE THE VERBRUGGEN PALLETISER IN ACTION HERE…

Efficient Box, Bag & Crate Palletising Solutions

Palletising solutions have become increasingly popular in the agricultural industry, especially with the use of palletising machines.

These machines have revolutionised the way products are stacked and transported, offering greater efficiency and cost savings for farmers and growers.

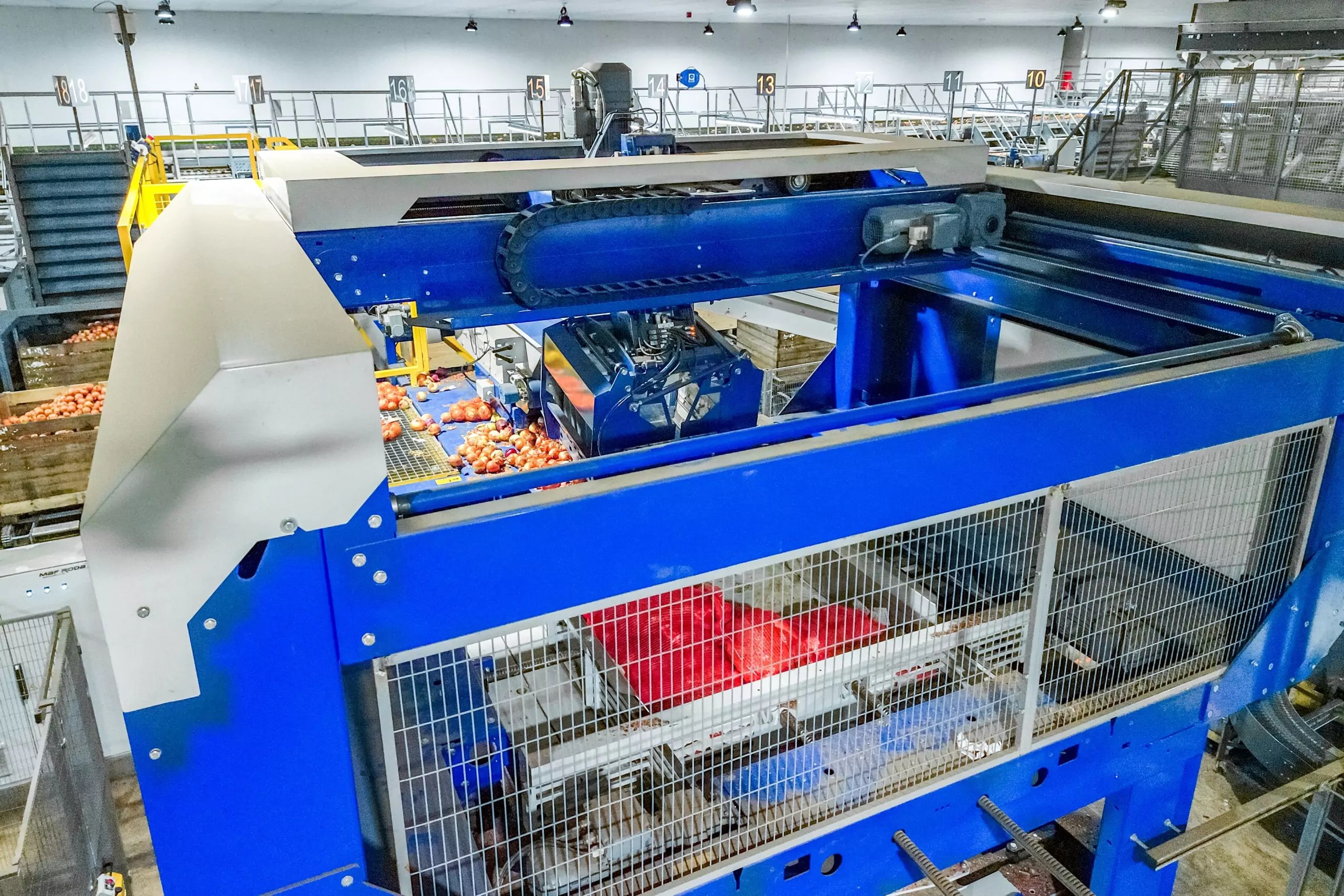

In the agricultural industry, palletising machines are commonly used to stack crates filled with fruit and vegetables onto pallets. These machines have the ability to stack crates in a precise and efficient manner, ensuring the maximum number of crates can be loaded onto a single pallet.

Palletisers can also be used to stack boxed and bagged product onto pallets, including palletising bags of potatoes, nets of onions and sacks of carrots and beetroot.

Verbruggen palletisers can handle bags from 2,5 kg (5 lbs) up to bags of 75 kilos (165 lbs). The palletisers can also handle boxes of different sizes as well as bags in boxes.

Palletising machines can also improve safety in the workplace by minimising the need for manual lifting and handling. This helps to prevent workplace injuries and increases productivity by allowing workers to focus on other tasks.

Verbruggen has extensive experience in stacking various agricultural product types including a wide variety of root crops, most commonly potatoes, onions, carrots and beetroot. Their team of engineers are continually innovating and developing their machines and software and Tong is proud to work closely with the Verbruggen team to provide advanced palletising solutions, and timely support and service for Verbruggen equipment, to vegetable packers and producers throughout the UK.