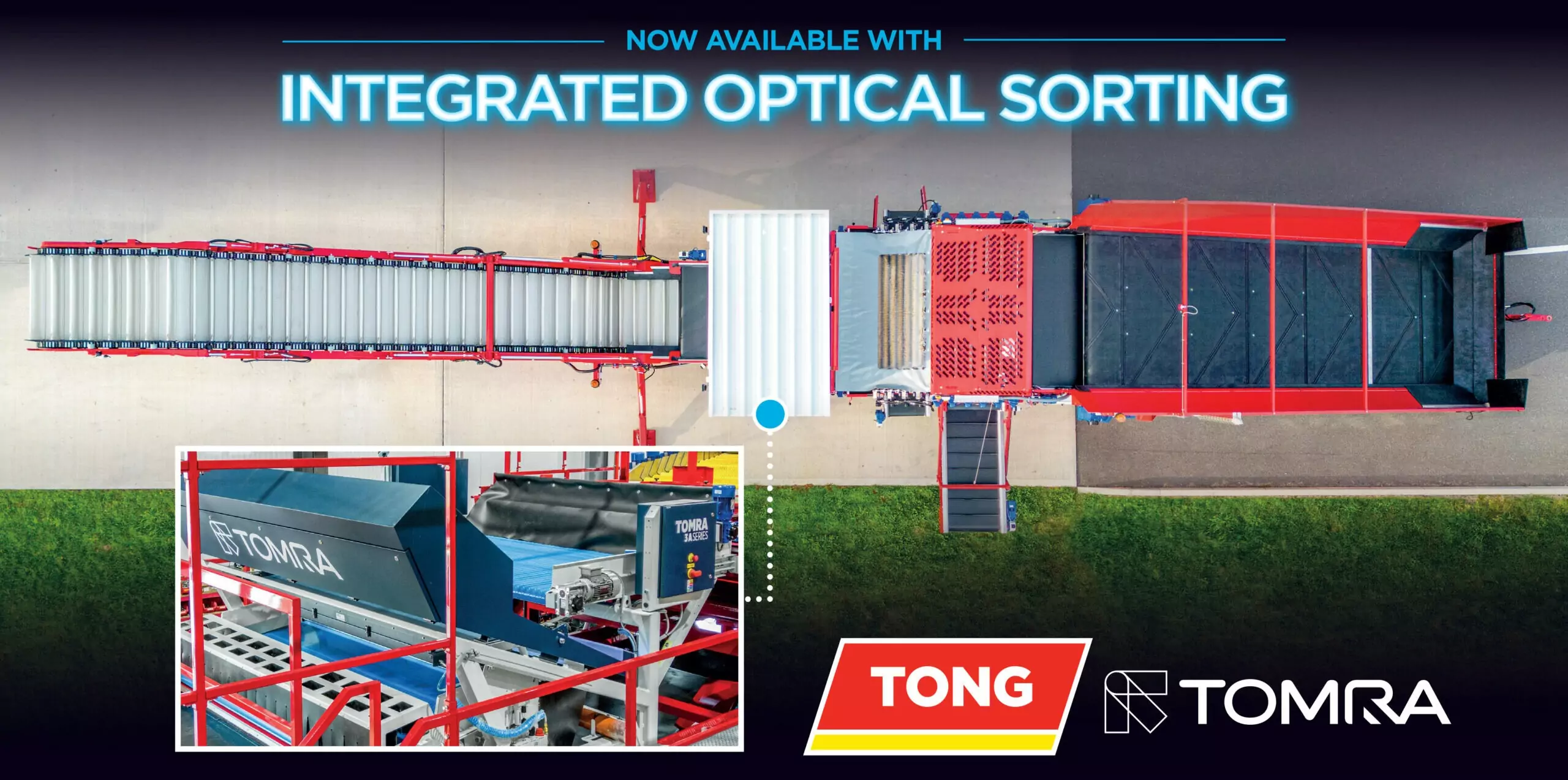

THE ULTIMATE FIELDLOADING MACHINE

The FieldLoad PRO is Tong’s industry leading fieldloader, built to offer maximum flexibility in post-harvest vegetable cleaning and loading.

Designed to streamline post-harvest handling, the FieldLoad PRO operates with minimal labour requirements, maximises yield and removes the need for unnecessary carting of soil and associated costs.

Tong’s unrivalled fieldloader is suitable for multi-crop use and is popularly used on potatoes, carrots, onions, parsnips, bulbs and more. With throughputs of up to 100 tons per hour, the FieldLoad PRO is a versatile and fully-mobile cleaning and loading powerhouse that makes light-work of loading crop straight from the field.

AUTOMATED HANDLING

MINIMISE LABOUR

The FieldLoad PRO ensures maximum labour efficiency with its ability to run continuously with minimal staffing requirements.

ADAPTABLE OPERATION

MAXIMISE FLEXIBILITY

The FieldLoad PRO allows you to be agile in meeting contract demands. In the field, on the farm, into lorries, boxes or store.

High Throughput

up to

100 tph

The FieldLoad PRO is proven to dramatically improve crop loading times, comfortably handling up to 100 tons of crop per hour.

LEAVE SOIL & DEBRIS

IN THE FIELD

The FieldLoad PRO receives and cleans crop at high capacities straight from trailers filled by the harvester, dramatically reducing unnecessary transport of crop from field to farm.

Reducing ‘crop miles’ and the amount of harvest-related soil on the roads is at the top of the agenda for growers and producers worldwide. When used in the field, the FieldLoad PRO provides highly effective removal of soil and debris, leaving all waste in the field. Carting soil becomes a thing of the past!

SELECT YOUR CLEANER. TAILOR YOUR DESIGN

The new FieldLoad PRO from Tong is designed to be extremely versatile. As part of the design process, you can take your pick of one or any combination of Tong’s cleaning units, including the renowned EasyClean separator with Auto-Touch HMI controls, for unrivalled cleaning in all conditions.

You may prefer the high-speed PU coil cleaning system or star coil cleaning units, both of which are available as the sole cleaner within the fieldloader, or are commonly fitted after the EasyClean for effective removal of smalls.

This flexible design approach ensures your FieldLoad PRO is built to meet your exact requirements, with ultimate performance at the fore.

EASYCLEAN II SEPARATOR

Tong’s market-leading EasyClean separator offers truly unmatched crop cleaning performance and control with exceptional results on a wide variety of crop in all conditions. The EasyClean separator features Tong’s Blue Inverter Technology with an electric direct drive motor on every shaft, delivering the very best energy efficiency as well as refined control of each shaft for optimum cleaning results.

When specified with an EasyClean separating system, the FieldLoad PRO is fitted with the cartridge-style EasyClean separator featuring the latest auto-reject function for automatic removal of foreign objects. Tong’s unrivalled knowledge and experience in effective crop cleaning means that when you choose the EasyClean, you are selecting the most effective separator on the market.

PU COIL CLEANER

Manufactured in a choice of polyurethane (PU) or Steel coil rollers, the Tong adjustable coil cleaner can be specified as your chosen cleaner separator in the FieldLoad PRO. Designed as an efficient cleaning system suitable for light soil conditions, the Tong adjustable coil cleaner can also be fitted after a Tong EasyClean separator, for sizing out smaller crop between 15mm to 55mm.

Built with 4, 6 or 8 rows of easily adjustable centre spiral coils/rollers, the coil cleaner is gentle on crop whilst effectively removing loose soil, small stones and clod from crop.

STAR CLEANER

The Tong star cleaner features 4, 6 or 8 rows of 14 or 18 fingered polyurethane (PU) stars. It can be specified as your chosen cleaner in the FieldLoad PRO. The star cleaner is ideal for light soil conditions, offering gentle and efficient soil, clod and stone removal. It can also be fitted with a VertiCam system for improved self-cleaning of stars.

Features

WIDE CART ELEVATOR

What makes the FieldLoad PRO different to other field loading machines on the market, is the option of a wider cart elevator, which can be specified up to 1.5m wide.

Manufactured with a fully folding, deep-flighted pocket elevator, the FieldLoad PRO ensures the gentlest transfer of crop into bulker lorries, box filling equipment and into store. As part of the machine’s custom-built design, Tong offers a range of elevators to suit individual requirements.

HEAVY DUTY SUPPORT LEGS

Built upon a heavy-duty chassis, the FieldLoad PRO features robust support legs for ultimate performance during operation. For complete convenience, the FieldLoad PRO support legs automatically position via remote control, for either operational or transport mode.

INSULATED INSPECTION CABIN

The FieldLoad PRO is built with a spacious, custom-designed inspection cabin. The cabin is fully insulated and fitted with LED inspection lighting, and is available with the option of energy-efficient heating.

HEAVY DUTY HOPPER CONSTRUCTION

With heavy duty steel gauge design consisting of chain and lathe construction, and heavy duty chains with a dual driven shaft, the fieldloader hopper offers the very best quality and reliability. When you choose the FieldLoad PRO you can be sure that the Tong hopper will stand up to demands for years to come.

ADVANCED CONTROL

For ultimate ease of operation, the FieldLoad PRO is available with the latest HMI touch screen controls, as well as a simple and convenient remote control that allows machine settings to be changed at the touch of a button.

In order to achieve the very best crop cleaning in all conditions, Tong Auto-Touch HMI touch screen controls allow operators to quickly and easily select the crop type and condition of each load. Users can select crop conditions such as ‘Wet’ or ‘Dry’ and crop type from the display menu. This simplicity in setting the machine to automatically change the speed, position and direction for different loads makes machine set-up exceptionally quick and easy.

BLUE INVERTER TECHNOLOGY

All Tong Fieldloaders are built with Tong’s Blue Inverter Technology, offering the very best energy efficiency. With all electric Inverter Variable Speed Drive, providing exceptional energy savings of over 50% in comparison to similar machines with a standard mechanical drive.

WATCH THE

FIELDLOAD PRO

IN ACTION

The FieldLoad PRO has proved to be a truly invaluable post-harvest asset to vegetable growers worldwide. Watch the videos to see how versatile the FieldLoad PRO is in loading bulker lorries, box fillers, into store etc. With every load, you have complete flexibility to load crop in whatever way you choose.