ECONOMICAL VEGETABLE WEIGHING

Tong in-bag vegetable weighers & baggers provide an economical and effective system for weighing small product and vegetables of all types into bags or nets, from 12.5kg to 50kg.

Particularly popular for weighing potatoes and onions, Tong in-bag weighers are also suitable for non-vegetable applications including weighing charcoal and bagging coal.

reliable

CONSISTENT weighing

Based on a simple yet effective, heavy duty design, the Tong weighers & baggers offer low maintenance and reliable weighing of a wide range of small product and root crop.

flexible

12.5kg to 50kg bags

The in-bag vegetable weigher can be calibrated to weigh a wide range of bag weights, offering an economical and versatile machine for 12.5kg to 50kg bags.

high throughput

up to 10 TPH

Tong vegetable weighers & baggers offer high capacity performance at an affordable price, with the capability to weigh up to 10 tons of crop per hour.

FEATURES

HEAVY DUTY BELTS

Tong weighers & baggers are renowned for their high quality build, including heavy duty belts for ultimate longevity. The 425 weigher features a single 300mm wide belt.

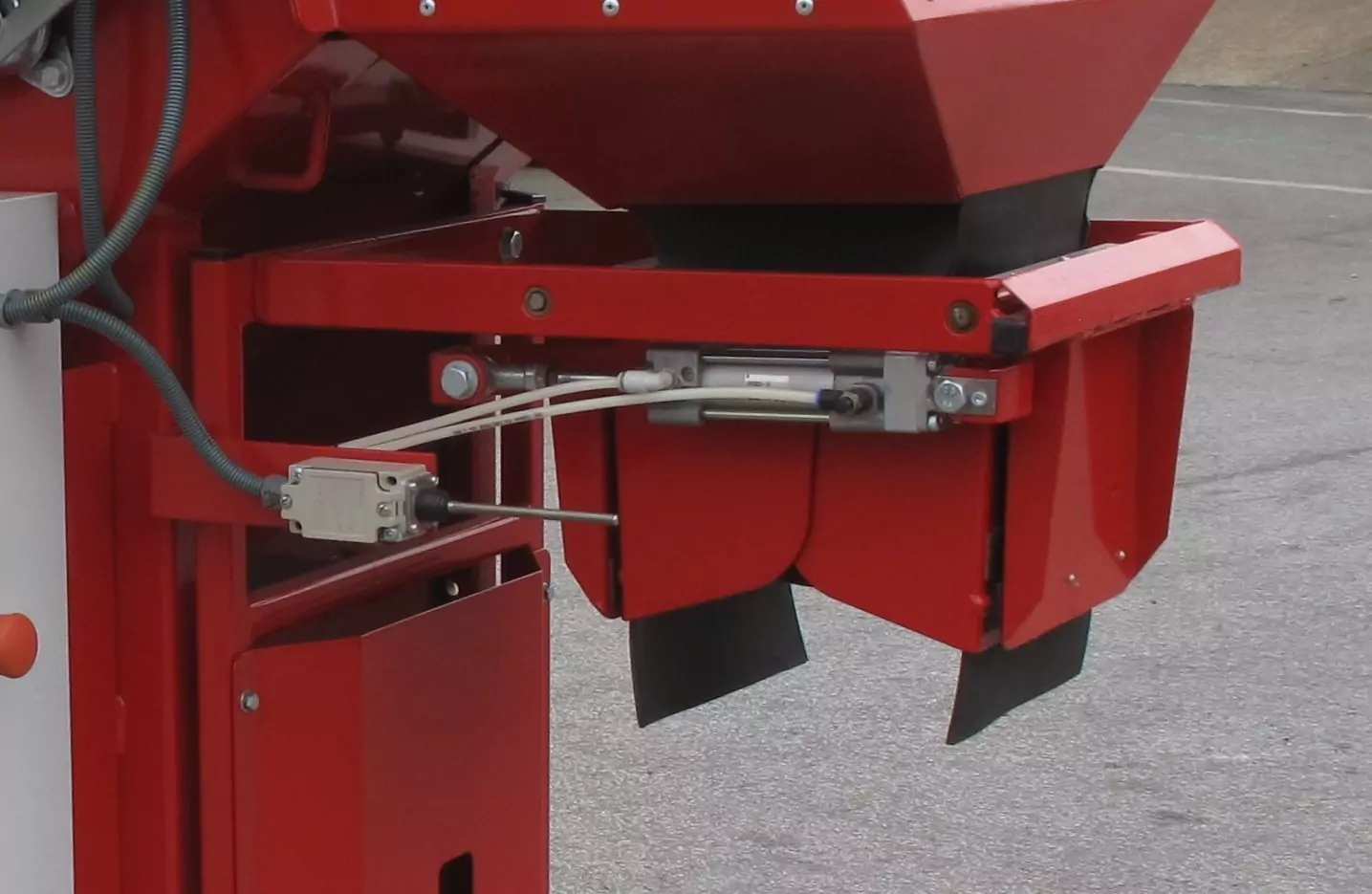

SECURE BAG CLAMP

Tong in-bag vegetable weighers weigh crop in the bag. The machine’s heavy duty pneumatic bag clamp holds the bag in place securely throughout the weighing process, releasing the bag once the desired weight is achieved.

BAG PLATFORM

An adjustable height bag platform can be fitted as an option Tong weighers & baggers, giving a closely positioned platform for filled bags to be discharged onto, also ensuring minimal drop and easy exchange of filled bags.

BAG CONVEYOR

Tong weighers are available with the option of a heavy duty bag conveyor with integrated side guards, to effectively receive filled bags. The bag conveyor is manufactured with a 2.5m long x 300mm wide grip top belt as standard. A popular option in conjunction with a hand-held stitcher, passing filled bags along the conveyor, making the entire bag weighing and stitching process run more smoothly.

425

VEGETABLE WEIGHER

The Tong 425 compact weigher bagger is a semi-automatic vegetable bagging system, offering effective weighing and bagging of bags between 25kg to 50kg, at up to 4 tonnes per hour.

Suitable for use on a wide range of vegetables including potatoes, carrots, onions and more, the 425 weigher bagger is also popularly used for bagging coal and charcoal. Designed with a single flighted belt, the 425 weighers is powered by a fixed speed motor and can be specified to suit single or three-phase power supply.

The 425 compact weigher bagger is a mechanical weigher in which desired weight is adjustable by turning a handle, increasing or decreasing the tension on a pair of heavy-duty springs. When a bag is placed under the outlet chute, supported by the weigher’s integrated bag platform, the start button is pressed and the product feeds up the elevator and into the bag. As the weight is reached, a micro-switch stops the belt and the bag is removed, and the bag is then replaced and the process is repeated.

So, if you are looking to gently and efficiently bag vegetables but don’t require the higher throughputs of Tong’s larger automatic weighers & baggers, then the 425 compact weigher bagger could be the affordable weighing solution to suit your needs.